AZ Cemented Carbide

thermal Spray Powder

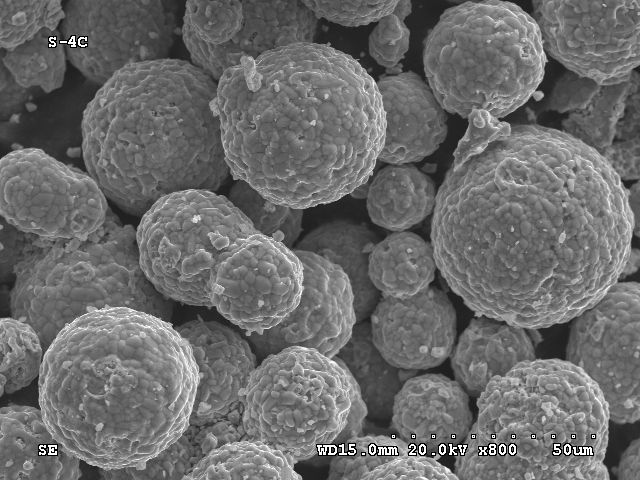

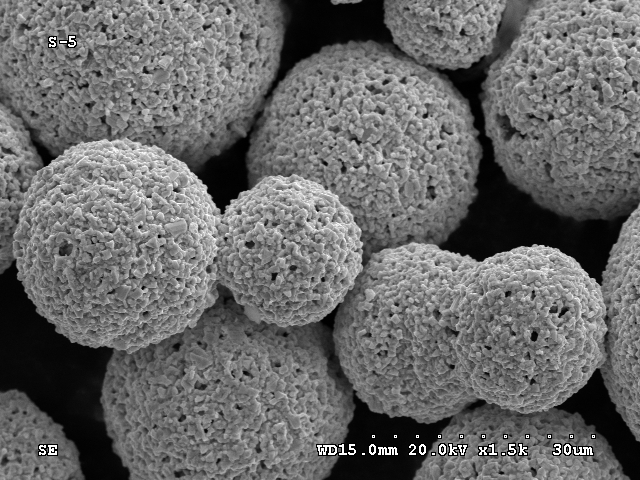

Property: High wear resistance, corrosion resistance and high temperature oxidation

Appearance: Dark grey particles with metal-luster

Applications: Heat the spray powder to the state of melting or half-melting, by applying electric arc, plasma arc, or burning flame, with the help of flowing force of the flame itself, or additional high velocity airflow, to atomize the spray powder, then spray it to the pre-treated surface of parts at certain speed to adhere to the surface, making the parts abrasive resistance, erosion resistance, high temperature oxidation resistance and impact resistance. Materials that could be sprayed on include almost all solid engineering materials, such as metal, alloy, ceramics, metal ceramics, plastics and compound of materials composed of them.

10Co4Cr Spray Powder

12Co Spray Powder

We always strive to provide our customers with most satisfying service with integrity and credibility.

Most of our products have the first class quality in the world, with multiple national patents in China. They are widely used in the industries of construction, mining, metallurgy, oil, chemicals and machineries.

Copyright 2012 AZ Cemented Carbide. All rights reserved.